Leather is a versatile, hardwearing, and functional textile, used for a variety of uses from interior textiles to wearable garments. Although leather is in no way unique to Scotland, it has a long history of production within Scotland. It’s used for its strength and longevity, and is considered by many to be a sustainable and renewable material.

The characteristics of leather vary depending on the animal that the hide has come from, as well as methods of tanning and finishing. It can be produced to be buttery soft, or firm and abrasion resistant, and has a wide range of uses from furniture, shoes, apparel, and accessories. Some common characteristics across varieties are malleability, breathability, and durability.

Leather is largely produced as a by-product of the meat and dairy farming industries. It can be produced from a range of animal skins and hides, including cattle, deer, and even fish. Cattle hide is the most commonly used raw material, making up around 65% of all leather produced. In 2015 there were an estimated 1.8 million cattle in Scotland – a figure which has been steadily falling from its peak in the mid-1970s. The vast majority of these cattle are used for the production of meat and dairy rather than leather, and as leather is overwhelmingly a by-product of the meat and dairy industry, it is difficult to find figures for how many leather producing animals there are.

Leather varies as a material depending on lots of different factors, including the animal the hide or skin came from, the tanning process, and the finishing techniques used. It’s an incredibly versatile material and is used in a wide variety of settings. It is a popular material in a wide range of industries including automotive, aviation, bus, coach and rail, furniture, fashion, equestrian, and protective equipment.

There are a number of well established heritage factories within Scotland who produce leather such as Muirhead, Bridge of Weir Leather, and W.J. & W. Lang on the West Coast of Scotland, as well as a handful of small producers across the country. These smaller producers include Skyeskyns on the Isle of Skye who specialise in tanning sheepskin, J Hewitt & Sons in Edinburgh who specialise in producing leather for bookbinding, and Woodland Tannery in Fife – a social enterprise that specialise in producing leather from wild deer hides, sheepskin from local farms, and fish skin from salmon using natural materials based on traditional recipes in the tanning process.

It can also be used to make smaller objects such as brush backs and toys, and is easily turned and carved making it ideal for hand crafted spoons, bowls and vessels.

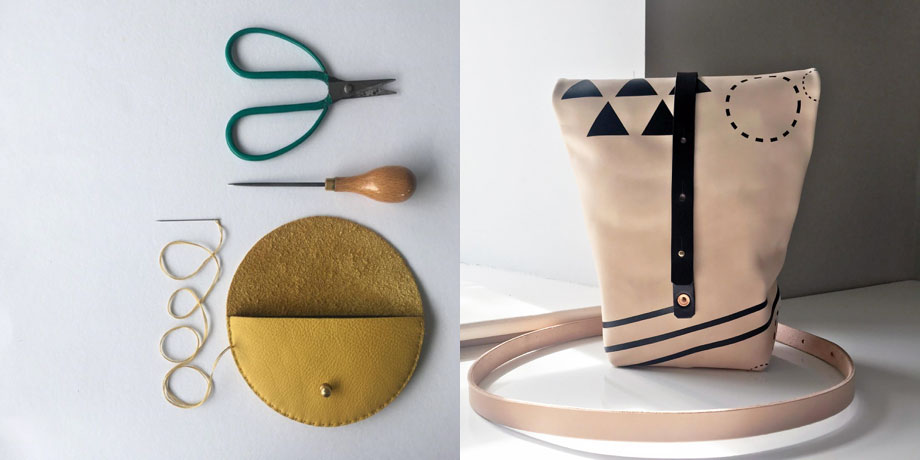

There are also a number of Designer/Makers working with leather in Scotland including Jude Gove, a Designer/Maker in Tayside who makes hand-stitched leather purses, and S.K. Works in Midlothian who make contemporary bags and accessories using leather embossed and screen printed with geometric patterns.

Leather is produced from the skin and hides of animals including cattle, deer, and fish – these are called pelts before they are processed into leather. Almost all of the leather that is produced commercially is a by-product of the meat and dairy industries and is otherwise considered a waste product. Nonetheless, the production of leather requires the animal to be slaughtered and there are significant animal welfare concerns to be taken into consideration around how the animal has been treated when alive, and the methods of slaughter used, which are enforced by law in Scotland and across the rest of the UK.

Once the pelt has been removed from the animal, it goes through a series of steps to transform it from rawhide to workable leather. This includes preparing, tanning, and crusting.

Before tanning the animal pelts have a limited storage time and need to be preserved during transportation. Occasionally they may be transported refrigerated, but more commonly they will be covered in preserving salt. Before they can be tanned, the pelts to be cleaned and prepared to remove the preserving salt, any dirt, and any remaining flesh. The hair is usually removed at this point too, except for in the case of ‘hair-on’ leather where it is left intact. Once they have been cleaned thicker hides may be split – the top, grain layer is used to make full grain or nubuck leather, and the bottom layer is used to make suede or split leather.

Once the hides and skins have been cleaned and prepared they move onto the tanning process. The tanning process stabilises the protein structure making them durable, chemical resistant, and less susceptible to decomposition. At this point the pelts are transformed into leather. The 3 key methods used to tan leather include – chrome tanning, vegetable tanning, and chrome-free tanning.

Finally, the leather goes through the crusting process. This softens and dries the leather piece, and gets it ready for any final finishing such as dyeing or sanding.

Leather has a lot of positives and is, on the whole, a very sustainable material. It can be recycled, is easy to repair, renewable, and is very long-lasting when cared for correctly. It is also naturally resistant to stains and odours which reduces the amount of cleaning and laundering required, and it doesn’t shed microplastics that contribute to water pollution like synthetic textiles do. Globally, leather manufacture saves an estimated 7 million tonnes of animal pelts from going to landfill each year by transforming by-products of food industries into a usable and valuable material.

On the other hand, farming of cattle and other animals contributes to rising levels of methane in the atmosphere, and processing and tanning leather can use large volumes of water and some chemicals used in the tanning process can contribute to environmental pollution. That said, these issues are not unique to the production of leather, but are widespread issues in the production of textiles in general.

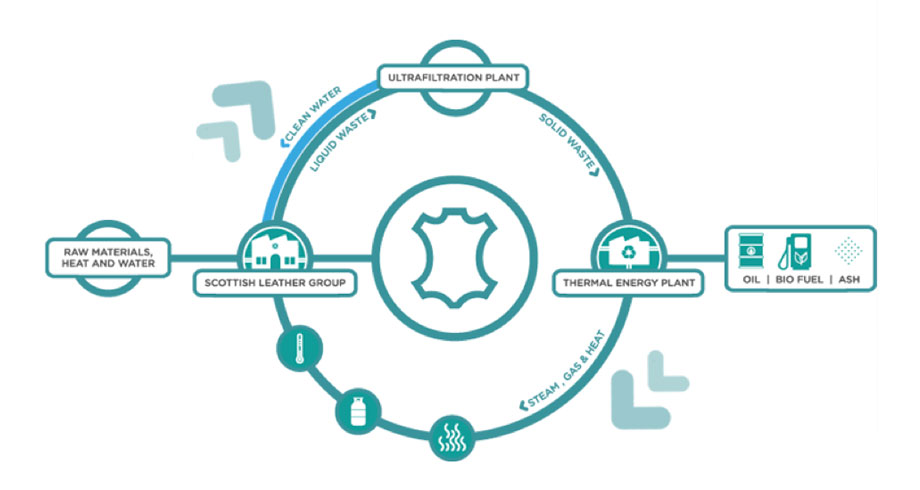

In recent years there have been efforts and investments within the leather industry to produce leather in an environmentally sustainable fashion. The Scottish Leather Group is a trio of leather manufacturers on the west coast who operate a zero waste policy in order to reduce their impact. In 2009 they collectively built a Thermal Energy Plant (TEP) which allows them to convert waste from the production processes into energy. Before the construction of the TEP this waste would have ended up in landfill, but is now routed back to the factories to be used in the manufacture of more leather.

Many people avoid the use of leather for ethical and moral reasons, such as vegans and vegetarians, but many of the alternatives also come with their own environmental concerns. From a purely environmental and sustainability perspective, while the meat and dairy industries continue to produce such a large volume of waste material the production of leather could be considered a sustainable practise that reroutes large amounts of waste from landfill.

“SLG Sustainability – Zero Waste”. Scottish Leather Group, http://www.scottishleathergroup.com/Sustainability/Sustainability.aspx. Accessed 25th February 2021.

“5.2 Cattle”. Economic Report on Scottish Agriculture, 2016, https://www.gov.scot/publications/economic-report-scottish-agriculture-2016/pages/34/. Accessed 25th February 2021.

Burnley, Lottie. “Five Manufacturers for Leather in Scotland”. Make Works, https://make.works/blog/five-best-fabricators-for-leather. Accessed 25th February 2021.

“About Us”. Woodland Tannery, https://woodlandtannery.co.uk/about/. Accessed 25th February 2021.

“Muirhead Leather”. Muirhead Leather, https://www.muirhead.co.uk/. Accessed 25th February 2021.

“Why Use Leather? The Characteristics and Properties of Leather”. Leather Naturally, https://www.leathernaturally.org/Education/Fact-Sheets/Benefits/Why-use-leather-The-characteristic-and-properties. Accessed 25th February 2021.

“How is Leather Made?”. Leather Naturally, https://www.leathernaturally.org/Education/Fact-Sheets/Manufacturing/How-is-leather-made. Accessed 25th February 2021.

“Fabric Guide: Learn About Leather”. Masterclass, https://www.masterclass.com/articles/learn-about-leather#what-is-leather. Accessed 25th February 2021.

“The Sustainability of Leather – FAQ”. Leather Naturally, https://www.leathernaturally.org/Education/Fact-Sheets/Environment/The-Sustainability-of-Leather-FAQ. Accessed 25th February 2021.

“Leather Sector Plan”. Scottish Environmental Protection Agency,

https://sectors.sepa.org.uk/media/1116/leather-sector-plan.pdf. Accessed 25th February 2021.